How can we choose the right valves in water treatment projects? (Part 2)

- KEPLER TEAM

- Oct 27, 2021

- 3 min read

The previous article talked about gate valves and ball valves commonly used in the water treatment industry. In this article, we will introduce the other two kinds of valves.

1. Butterfly valve

Advantage:

(1). It is convenient and quick to open and close, labor-saving, low fluid resistance, and can be operated frequently.

(2). Simple structure, small size and light weight.

(3). Mud can be transported, and the accumulation of liquid at the pipe mouth is the least.

(4). Under low pressure, good sealing can be achieved.

(5). Good adjustment performance.

Shortcoming:

(1). The working pressure and working temperature range are small.

(2). Poor airtightness.

Applications

Butterfly valves are suitable for flow regulation. Since the pressure loss of the butterfly valve in the pipeline is relatively large, it is about three times that of the gate valve. Therefore, when selecting the butterfly valve, the influence of the pressure loss of the pipeline system should be fully considered, and the sturdiness of the butterfly plate to withstand the pressure of the pipeline medium when it is closed should also be considered. sex. In addition, it is necessary to consider the limitation of the working temperature that the elastic valve seat material can withstand at high temperatures. The structural length and overall height of the butterfly valve are small, the opening and closing speed is fast, and it has good fluid control characteristics. The structural principle of the butterfly valve is most suitable for making large-diameter valves. When the butterfly valve is required for flow control, the most important thing is to correctly select the size and type of the butterfly valve so that it can work properly and effectively.

See the models:KPL-Q97 Butterfly valve

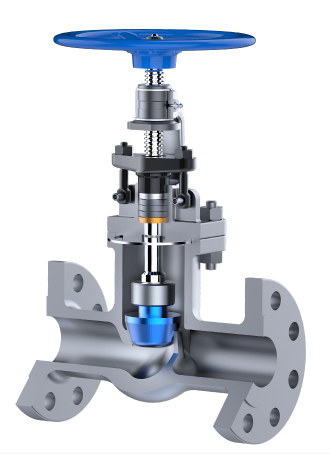

2. Globe valve

The globe valve is a forced sealing valve, so when the valve is closed, pressure must be applied to the disc to force the sealing surface to not leak.

Since the opening or closing stroke of the valve stem of the shut-off valve is relatively short, and it has a very reliable shut-off function, and because the change of the valve seat port is proportional to the stroke of the valve disc, it is very suitable for flow adjustment. Therefore, this type of valve is very suitable for use as a shut-off or adjustment and throttling.

The selection principle is:

(1) Stop valves should be used on pipelines or devices for high temperature and high pressure media. Such as thermal power plants, nuclear power plants, high-temperature and high-pressure pipelines of petrochemical systems.

(2) On pipelines that do not require strict flow resistance on the pipeline. That is, where the pressure loss is not considered.

(3) Needle valves, instrument valves, sampling valves, pressure gauge valves, etc. can be used for small valves.

(4) There are flow adjustment or pressure adjustment, but the adjustment accuracy is not high, and the pipe diameter is relatively small, such as the pipe with a nominal passage of ≤50mm, it should be selected.

(5) Small fertilizers and large fertilizers in synthetic industrial production should use high pressure angle stop valves or high pressure angle throttle valves with a nominal pressure of PN160 and a nominal pressure of 16MPa or PN320 and a nominal pressure of 32MPa.

(6) In the desilication workshop of the alumina Bayer process and the pipelines that are prone to coking, it is easy to choose the direct-flow stop valve or direct-flow throttle valve with the valve body separated, the valve seat can be removed, and the cemented carbide sealing pair.

(7) For water supply and heating projects in urban construction, for pipelines with smaller nominal diameters, stop, balance valves or plunger valves can be used, such as pipelines with a nominal passage of less than 150mm. The most obvious advantage is that during the opening and closing process, the friction between the disc and the sealing surface of the valve body is smaller than that of the gate valve, so it is wear-resistant. The opening height is generally only 1/4 of the diameter of the valve seat passage, so it is much smaller than the gate valve. Usually there is only one sealing surface on the valve body and the valve disc, so the manufacturing process is relatively good and easy to maintain.

Comments