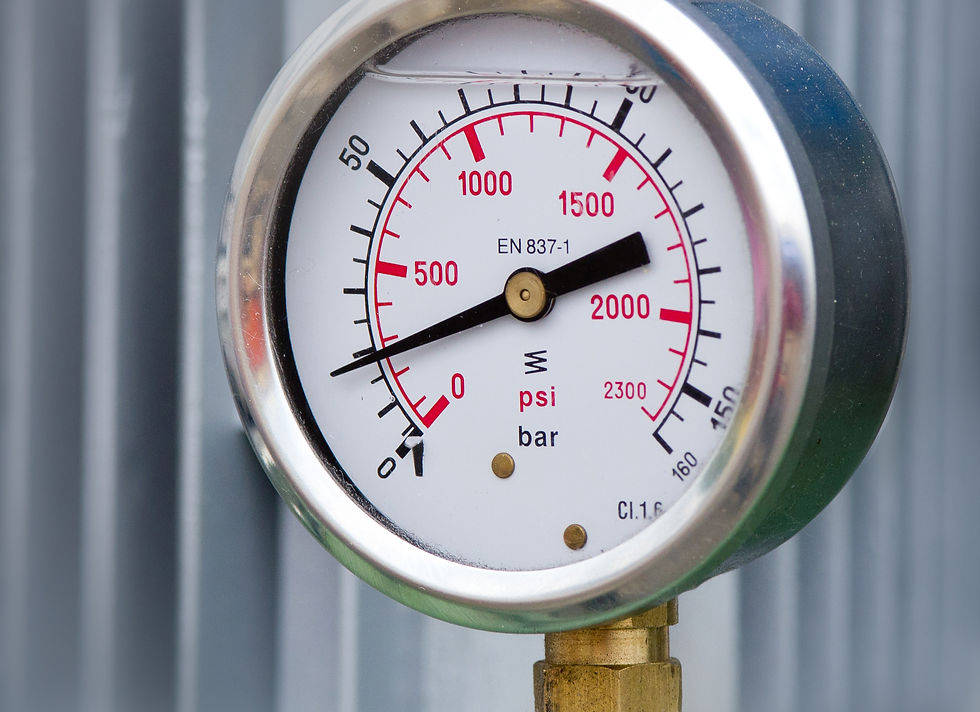

Do you know the Common Technical Problems of Valve Pressure Test?

- KEPLER TEAM

- Dec 6, 2021

- 3 min read

(1) Exclude valve air as much as possible during hydraulic test.

(2) During the test, the valve installation position should be in an easy-to-check direction.

(3) During the strength test of cast iron valves, tap the valve body and bonnet with a copper hammer to check for leakage.

(4) For valves in the form of welded connection, if the pressure test with the pallet fails, the taper seal or O-ring seal can be used for the pressure test.

(5) After the valve pressure test is completed, the water in the valve should be removed and wiped clean in time, and the test record should be made.

(6) The pressure should be gradually increased during the test, and sudden and sudden increase in pressure is not allowed.

(7) When the valve is tested, except for the plug valve that allows the sealing surface to be oiled, other valves are not allowed to be oiled on the sealing surface.

(8) The throttle valve shall not be tested for the tightness of the closing parts, but shall be tested for the strength and the tightness of the packing and gaskets.

(9) During the pressure test, the closing force of the valve is only allowed by one person's normal physical strength to close; no lever or other tools (except torque wrenches) can be used to add force. When the diameter of the handwheel is larger than 320mm, two people are allowed to work together. closure.

(10) During the pressure test of the valve, the pressing force of the blind plate on the valve should not be too large, so as not to deform the valve and affect the test effect (if the cast iron valve is pressed too tightly, it will be damaged).

(11) For valves with a driving device, the driving device should be used to close the valve when testing its tightness to conduct a tightness test. For manual actuation devices, a sealing test of the dynamic closing valve shall also be carried out.

(12) The bypass valve installed on the main valve after the strength test and tightness test shall undergo strength and tightness tests on the main valve; when the main valve closing element is opened, it should also be opened.

(13) The strength and tightness test should be done for the installation of safety valves. Low-pressure safety valves should be randomly checked 20%, if they are unqualified, 100% should be checked; medium and high-pressure safety valves should be 100% checked.

(14) For valves with upper seals, the packing should be taken out for a tightness test. After the upper seal is closed, check for leakage. When using gas as a test, put water in the stuffing box to check. When making the packing tightness test, the upper seal is not allowed to be in a tight position.

(15) The duration of strength test and tightness test is generally 2~3min, and important and special valves should last for 5min. The test time for small-bore valves can be correspondingly shorter, and the test time for large-bore valves can be correspondingly longer. During the test, if in doubt, the test time can be extended. During the strength test, no sweating or leakage of the valve body and valve cover is allowed. For the sealing test, the valve of the rotor pump is generally only performed once, and the main valves such as safety valve and high-pressure valve need to be performed twice. During the test, for low-pressure, large-diameter unimportant valves and valves with regulations that allow leakage, a small amount of leakage is allowed; due to the different requirements for general valves, power station valves, marine valves and other valves, leakage requirements It should be implemented in accordance with relevant regulations.

Under normal circumstances, the valve is not subjected to a strength test, but the valve body and bonnet or the valve body and bonnet damaged by corrosion should be subjected to a strength test after repair. For safety valves, the constant pressure and return pressure and other tests shall comply with the specifications and relevant regulations. I hope that the above sharing of common technical problems of the fifteen major valve pressure tests will be helpful to you!

Comments